Reinforced concrete is the backbone of modern construction, providing strength, durability, and versatility to countless structures worldwide. Yet, achieving optimal results with reinforced concrete requires more than just pouring a mix into a mold and letting it set. Proper design and installation are crucial to ensure the structural integrity and longevity of the concrete.In this guide, we delve into the intricacies of designing and installing reinforced concrete, covering essential principles, techniques, and considerations. Whether you’re a seasoned engineer, a construction professional, or a DIY enthusiast embarking on a project, mastering these fundamentals is essential for success.From understanding load-bearing capacities to selecting the right reinforcement materials, from ensuring proper curing to implementing effective quality control measures, this comprehensive guide will equip you with the knowledge and skills needed to tackle reinforced concrete projects with confidence and precision. Join us as we unlock the secrets to mastering the art of reinforced concrete design and installation.

Best Practices in Reinforced Concrete Formwork Construction

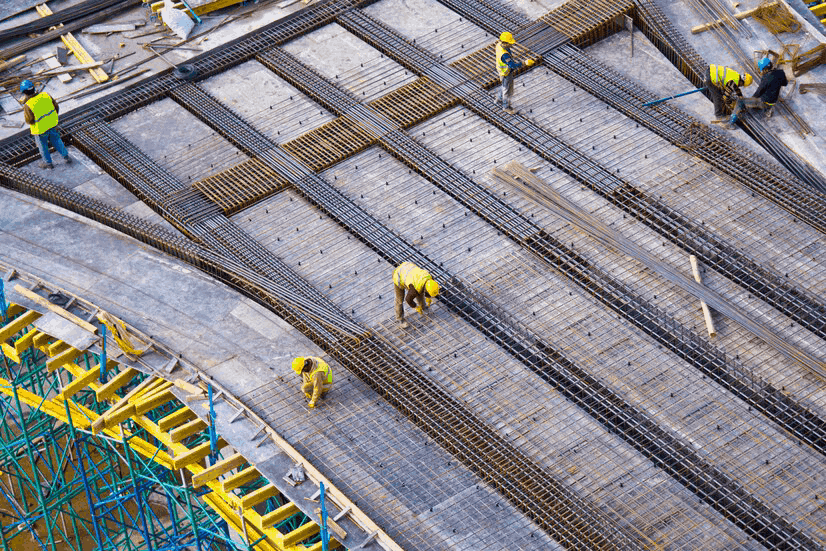

Formwork is the backbone of any reinforced concrete structure, providing the mold that shapes the final product. Proper formwork construction is essential for ensuring the structural integrity, quality, and safety of the concrete elements. In this guide, we’ll explore eight best practices to follow when constructing formwork for reinforced concrete projects.

Select High-Quality Materials

Choose formwork materials that are durable, dimensionally stable, and capable of withstanding the pressures exerted by fresh concrete. Common formwork materials include timber, plywood, steel, and aluminum. Ensure that the selected materials are free from defects and properly treated to resist moisture and swelling.

Properly Support Formwork

Ensure that formwork is adequately supported to withstand the weight of fresh concrete and any additional loads. Use strong and stable supports such as adjustable props, shoring towers, or scaffolding. Distribute loads evenly to prevent deflection or failure of the formwork during concrete placement.

Pay Attention to Alignment and Levelness

Achieving precise alignment and levelness is crucial for producing smooth and uniform concrete surfaces. Use laser levels or string lines to ensure that formwork components are aligned and leveled accurately. Regularly check and adjust the formwork during construction to maintain the desired alignment and levelness.

Provide Sufficient Reinforcement and Bracing

Reinforce formwork panels and joints to resist the lateral pressure exerted by fresh concrete. Install diagonal braces, tie rods, or walers to stabilize the formwork and prevent bulging or deformation. Ensure that bracing components are securely anchored and properly tightened to maintain structural stability.

Use Release Agents Appropriately

Apply release agents to formwork surfaces to prevent adhesion between the concrete and the formwork. Choose a suitable release agent based on the type of formwork material and the desired finish of the concrete surface. Follow manufacturer recommendations for application methods and ensure thorough coverage to facilitate easy formwork removal.

Designing for Strength: Key Principles in Reinforced Concrete Structural Design

Designing reinforced concrete structures for strength requires a deep understanding of engineering principles and material behavior. In this guide, we’ll highlight key principles essential for ensuring the strength and integrity of reinforced concrete elements.

- Load Analysis: Perform thorough load analysis to determine the magnitude and distribution of loads acting on the structure, including dead loads, live loads, wind loads, and seismic loads.

- Reinforcement Design: Design the reinforcement layout and detailing to resist the anticipated loads and ensure adequate strength, stiffness, and ductility in critical structural elements.

- Concrete Strength: Specify the appropriate concrete mix design to achieve the required compressive strength, considering factors such as curing methods, aggregate properties, and admixture use.

- Structural Stability: Ensure structural stability and resistance to overturning, sliding, and collapse through proper foundation design, shear wall placement, and lateral bracing strategies.

Designing for strength in reinforced concrete structures requires a holistic approach that considers structural analysis, material properties, construction practices, and lifecycle considerations.

Materials Matter: Selecting the Right Components for Reinforced Concrete

Reinforced concrete is a versatile and durable construction material widely used in various infrastructure and building projects. However, the performance and longevity of reinforced concrete structures depend significantly on the selection of the right materials. In this guide, we’ll explore eight essential components for reinforced concrete construction and provide insights into how to choose them wisely.

Concrete Mix Design

The quality of concrete is paramount in reinforced concrete construction. Selecting the appropriate mix design involves considering factors such as strength requirements, durability, workability, and environmental conditions. Collaborate with experienced concrete suppliers or mix design experts to develop a custom mix that meets the specific needs of your project.

Reinforcement Steel

Reinforcement steel, commonly in the form of rebars or mesh, provides tensile strength to reinforced concrete elements. Choose high-quality steel with appropriate strength and ductility properties to resist structural loads and prevent corrosion. Consider factors such as rebar diameter, grade, coating, and spacing to ensure optimal reinforcement performance.

Admixtures

Admixtures are chemical additives incorporated into the concrete mix to enhance its properties and performance. Select admixtures based on the desired effects, such as improving workability, accelerating or retarding setting time, reducing water content, or enhancing durability. Consult with concrete suppliers or admixture manufacturers to choose the right combination for your project requirements.

Aggregates

Aggregates constitute the bulk of concrete volume and significantly influence its strength, durability, and workability. Choose aggregates with suitable particle size, shape, grading, and cleanliness to achieve the desired concrete properties. Consider factors such as aggregate source, quality control measures, and compatibility with the cementitious materials.

Cementitious Materials

Cement is the binder that holds the concrete mix together. Select cementitious materials, such as Portland cement, blended cement, or supplementary cementitious materials (SCMs) like fly ash or slag, based on performance requirements, environmental considerations, and project specifications. Balance factors such as strength, durability, sustainability, and cost-effectiveness when choosing cementitious materials.

Conclusion

Designing and installing reinforced concrete structures require careful planning, expertise, and adherence to industry standards. From understanding the specific project requirements to selecting the appropriate materials and construction methods, every step plays a crucial role in ensuring the safety, durability, and functionality of the final structure. By following the guidelines outlined in this blog, both professionals and enthusiasts can embark on their concrete endeavors with confidence, knowing they are equipped with the knowledge to execute their projects effectively.

For further inquiries or assistance with your reinforced concrete projects in Southern California, don’t hesitate to reach out to PMC INC at 562-905-3101. Our experienced team is ready to provide expert guidance and support to help you achieve your construction goals.